The dual mass flywheel

A mass flywheel is a mechanical tool meant to effectively store rotational energy. The tool has the potential to resist variations in rotational energy. Generally, the quantity of energy stored in them is directly related to the square of its rotational speed. The energy stored can thus be altered by modifying its rotational speed through the application of the torque brought into line with its axis of symmetry.

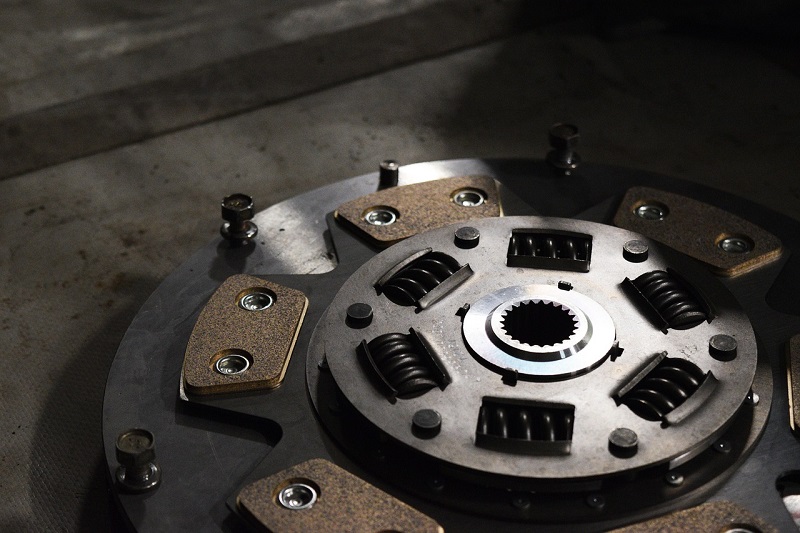

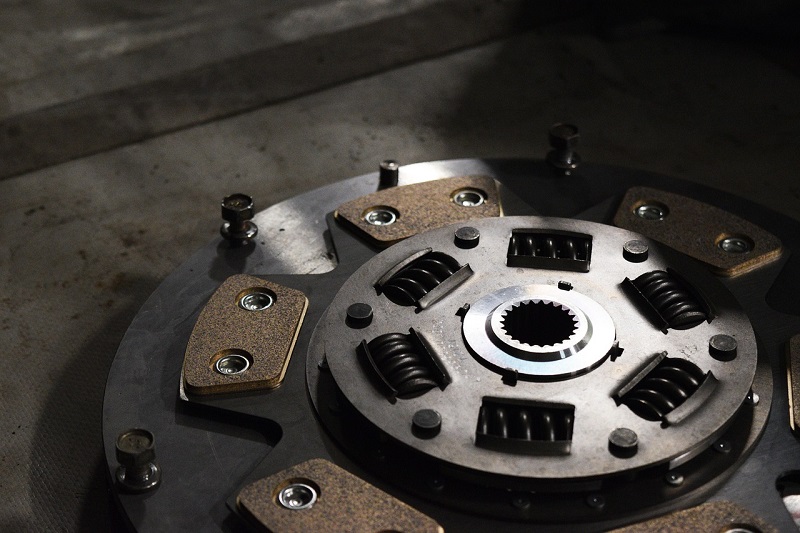

There are two types of mass flywheels, the dual and the standard one. A dual mass flywheel is divided into to two halves, the reason behind the name, with springs embedded between them to dampen the variation in torque and the acceleration of the rotation. This smoothens the vibrations leading to a smoother drive. Dual flywheel often wears out easily and can be too costly to repair or replace.

The purpose of the dual flywheel is to lessen noise and vibrations. Any kind of roughness is absorbed by the springs embed between the masses. It is prudent to note that a dual flywheel acts as a shock absorber. Each of the flywheels is a strong connection with a soft spring in between that takes some sorts of jolts away from accelerations and gear changes.

Table of Contents

Types of Dual Mass Flywheel

The principal type is referred to as the planetary DMF. The planetary gear along with torsional integrated into the core flywheel. This core flywheel is subdivided into two, the primary and secondary opinion-connected masses.

Between these two, there are four distinct types of bent springs:

- The individual bent spring

- One-phase bent spring, also known as parallel springs

- Two-phase bent springs in parallel

- Three phases bent spring. It is curved and characterized by an outer and duo springs with various elastic features fitted in series.

Symptoms of Failure

How can one tell there is a failure in the flywheels? Well, the following are some of the ways one can discern that:

-

Noise

This is a clear indication that something is messy. The noises can be too loud and where this happens, replacement should be done with no delay.

-

Slipping

Generally slipping emanating from the wear in the clutch is often accompanied by a burning smell. Where there is no smell, it is the flywheel that is slipping and replacement should be instant.

-

Vibrations

Vibrations can be evident even on the floor of the car and are often due to the failure of the springs as well as the rest of the internal components. This condition results in the inability of the flywheel to inhibit the vibrations and therefore replacement should be done.

Besides, you can have a visual inspection of the device. The following are some of the things you can do:

- Examine the friction surface maybe there could be extreme heat checks and scoring. If this is the case, discard.

- You can as well check for excessive loss of grease resulting from high temperature.

- Look for visible damage in the ring gear and other parts within the bell-housing.

- Examine the rotational free play

- Examine the secondary plate rock.

Conclusion

It evident that flywheel is an important part of a car engine. This article has focused on the mass dual flywheel. So what can you do in case you discover a total failure? Well, you have two options. You can either replace it or convert it into a single mass flywheel.

GPS navigation for car offer really good feedback to drivers while giving them lots of time to prepare for any changes in streets and lanes. Read more about car navigation bz clicking on the link.

Also read article with title “Anti-Hail Cover: What Can I Use to Protect My Car from Hail?“.

From ther same Category:

- Important informations about car motor oil

- From the Ladder to the Monocoque for Different Types of Vehicles

- Never underestimate any part of the engine to replace

- Protect your car from unwanted damage

- How to Choose the Best Car Battery

- Expansion Valve Basics

- Driving bumps? No problem: he’ll take care of it!