Never underestimate any part of the engine to replace

Let’s face it: how much do we know about engines? How much maintenance are we able to do on our own? How well do we know the pieces that make it up? We could say: we know enough.

But here we have to change the engine valves and we are already in a crisis about where to find them among the accessories and spare parts for cars. Trust me: they’re not a piece to be underestimated.

Table of Contents

Valves: what they are

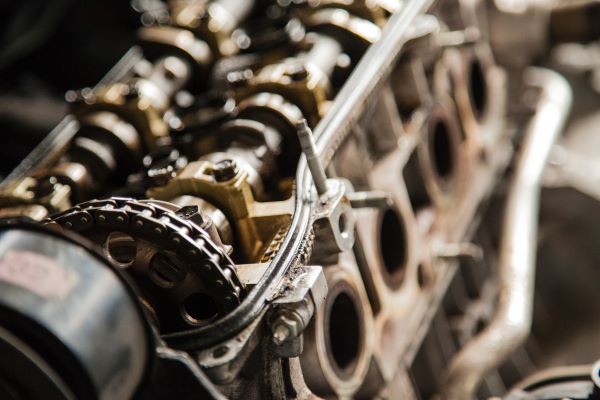

Engine valves are mechanical components used in internal combustion engines to allow or restrict the flow of fluid or gas to and from the combustion chambers or cylinders while the engine is running. Functionally they behave similarly to many other types of valves in that they block or pass flow. However, they are a purely mechanical device that interfaces with other engine components such as rockers to open and close in the correct sequence and with the correct timing.

The term engine valve can also refer to a type of check valve used for air injection as part of emissions control and exhaust gas recirculation systems in vehicles. First of all, make sure which tubes you need.

Engine valves are common to many types of combustion engines, regardless of whether they run on a fuel such as gasoline, diesel, kerosene, natural gas (LNG), or propane (LP). Engine types vary based on the number of cylinders which are the combustion chambers that generate power from the ignition of the fuel. They also vary according to the type of operation (2-stroke or 4-stroke) and the design positioning of the valves within the engine.

Valves: what they are for

This article will briefly describe the operation of engine valves in typical combustion engines, as well as present information on valve types and their designs and materials.

Let’s start with the operation of the engine

Four-stroke internal combustion engines use two main types of valves: the intake valve and the exhaust valve. The intake valves are opened to allow an air / fuel mixture to flow into the engine cylinders prior to compression and ignition, while the exhaust valves open to allow exhaust gases to be expelled from the combustion process after ignition occurs. Movement of the crankshaft transfers movement to the camshaft through a timing chain, timing belt, or other gear mechanism. Timing and alignment between the position of the crankshaft (which determines the position of the piston in the cylinder) and the position of the camshaft (which determines the position of the valves for the cylinder) are critical not only to maximum performance of the engine, but also to avoid interference between pistons and valves in high compression engines.

In the intake cycle, the intake cylinder piston slides down when the intake valve opens. The movement of the piston creates negative pressure which helps draw the air / fuel mixture into the cylinder. Soon after the piston has reached the lowest cylinder position (known as bottom dead center), the intake valve closes. In the compression cycle, the intake valve is closed to seal the cylinder as the piston rises in the cylinder to the highest position (known as top dead center), which compresses the air / fuel mixture to a small volume. This squeezing action serves to provide higher pressure against the piston when the fuel is ignited, as well as to preheat the mixture to promote efficient combustion of the fuel. On the power cycle, the air / fuel mixture ignites which creates an explosion that forces the piston to return to its lowest position and transfers the chemical energy released by burning the air / fuel mixture into the rotational motion of the crankshaft.

The exhaust cycle has the piston rising back up into the cylinder while the intake valve remains closed and the exhaust valve is now open. The pressure created by the piston helps force the exhaust gases out of the cylinder through the exhaust valve and into the exhaust manifold. Connected to the exhaust manifold is the exhaust system, a series of pipes that includes a muffler to reduce acoustic noise and a catalyst system to manage emissions from the engine’s combustion. Once the piston reaches the top of the cylinder in the exhaust cycle, the exhaust valve begins to close and the intake valve begins to open, restarting the process. Note that the cylinder pressure on the intake helps keep the intake valve open and the high pressure in the compression cycle helps keep both valves closed.

As you will have understood at this point, therefore, valves are not an accessory or an auto parts to be underestimated: only trust expert advice when you choose to replace them or you need them.

Auto parts can be a tricky topic that tends to get confusing. If you like do-it-yourself auto repairs, then you know how difficult it can be to find the right part at the right price. Read the Guide to the crazy world of spare parts!